The compression copper clamp is a type of clamp that is widely used in various industries and applications. It is designed to provide

a secure and efficient connection between copper pipes or cables. This type of clamp is commonly used in plumbing, electrical, and

telecommunications applications. The compression copper clamp is known for its high conductivity, excellent corrosion resistance,

and ease of installation. In this article, we will explore the detailed materials used in the compression copper clamp and explain why

it is the preferred choice for many applications.

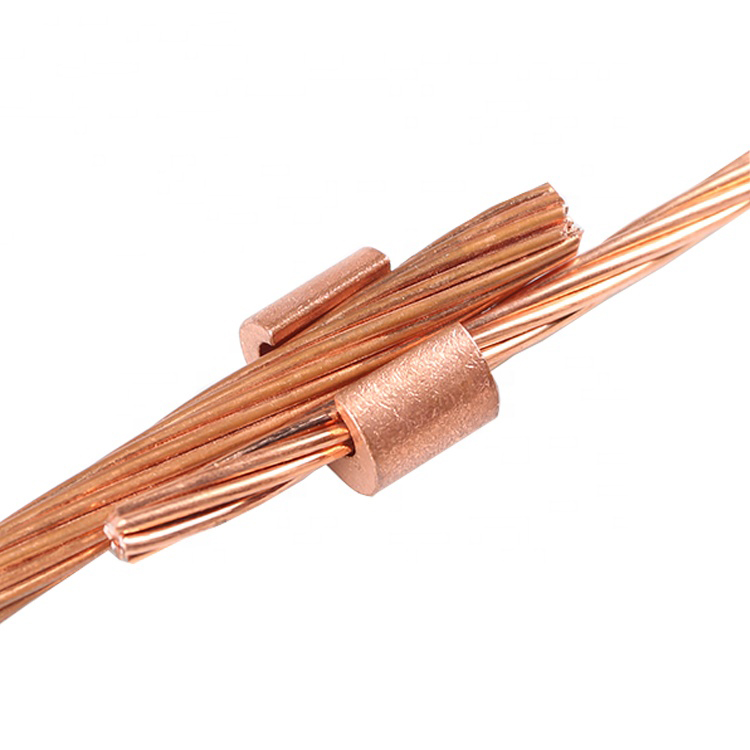

Introduction to the compression copper clamp The compression copper clamp is a specialized clamp used for connecting copper pipes

or cables. It consists of a copper clamp body and compression fittings that secure the connection. The copper clamp body is typically

made from high-quality copper, which exhibits excellent conductivity and durability. The compression fittings are designed to tightly

secure the pipes or cables, ensuring a reliable and long-lasting connection. The compression copper clamp is widely used due to its

ability to maintain electrical conductivity, resist corrosion, and provide a secure grip on the connected components.

Copper as the primary material Copper is the primary material used in the construction of compression copper clamps due to its

exceptional electrical conductivity. It allows for efficient transmission of electricity or signals through the connected pipes or cables.

Copper has a high conductivity rating, making it an ideal choice for applications that require low resistance and minimal power loss.

Additionally, copper is highly ductile, which allows for easy installation and shaping of the clamp to fit the specific requirements of

the application.

Corrosion resistance and durability Another significant advantage of using copper as the primary material for compression copper

clamps is its excellent corrosion resistance. Copper naturally forms a protective oxide layer, which inhibits further corrosion and

extends the lifespan of the clamp. This corrosion resistance makes copper clamps suitable for a wide range of environments, including

outdoor installations or areas with high humidity or chemical exposure. The durability of copper further ensures that the compression

copper clamp will withstand the test of time and maintain its performance even under demanding conditions.

Ease of installation and maintenance The compression copper clamp is designed to be easy to install and maintain. The compression

fittings provide a secure grip on the pipes or cables, eliminating the need for welding or soldering. This not only simplifies the

installation process but also allows for easy disconnection and reconnection if needed. The flexibility of copper also enables the clamp

to withstand minor vibrations or movements without compromising the connection. Additionally, the inherent antimicrobial properties

of copper make it a hygienic choice, particularly in plumbing applications where the prevention of bacterial growth is crucial.

the compression copper clamp is a popular choice for various industries due to its exceptional conductivity, corrosion resistance, durability,

ease of installation, and maintenance. The use of high-quality copper ensures reliable connections while providing longevity and efficient

transmission of electricity or signals. Whether in plumbing, electrical, or telecommunications applications, the compression copper clamp

offers a secure and efficient solution for connecting copper pipes or cables.

Post time: Aug-03-2023