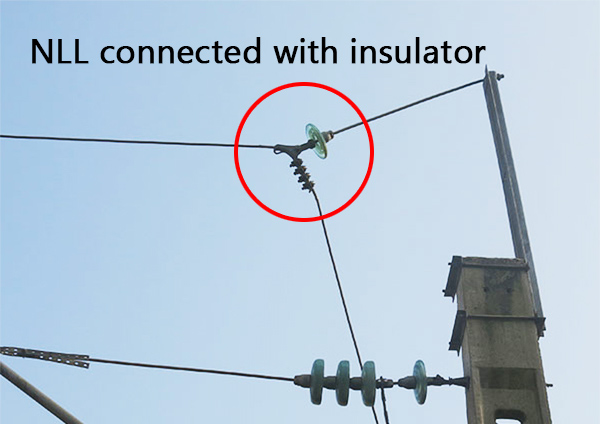

NLL connected with insulator

What are the different types of NLL tension clamp?

Bolt Type Tension Clamp NLL Series

NLL series bolt type tension clamp is mainly used in standing electric power line or substation, stationary

conduction line and lightning conductor and also be used in jointing the strain insulators by joining

hardware or jointing the lightning conductor with the perch.

It is designed for aerial lines up to 30kV.

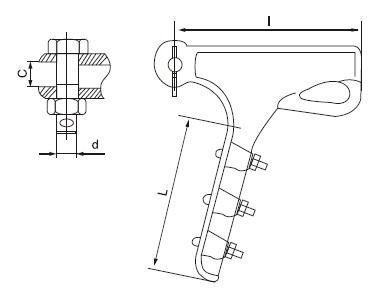

1) Be suitable for fixing insulated aluminum conductor or naked aluminum conductor on the rotate angle

or insulator of terminal strain pole, to fix and tighten the aerial conductor.

2) Material: body, keeper – aluminum alloy, split pin – stainless steel, others – hot-dip galvanized steel.

3) Grip strength of the clamp is more than 95% break strength of the conductor.

4) Insulation cover and strain clamp used together for insulation protection

|

Item |

Applicable conductor (mm) |

Dimensions (mm) |

Failure load (kN) |

Weight (kg) |

Bolt size |

|||

|

|

|

L |

I |

C |

d |

|

|

|

|

NLL-1 |

5.1-11.4 |

135 |

102 |

17 |

16 |

40kN |

0.75 |

2xM12 |

|

NLL-2 |

11.4-16 |

155 |

113 |

21 |

16 |

70kN |

0.9 |

2xM12 |

|

NLL-3 |

14.5-17.5 |

230 |

150 |

30 |

18 |

70KN |

1.84 |

3xM14 |

|

NLL-4 |

18-22.4 |

253 |

157 |

31 |

18 |

90KN |

2.32 |

3xM14 |

|

NLL-5 |

23-30 |

370 |

234 |

38 |

20 |

120KN |

4.5 |

5xM16 |

Before you buy and use tension clamp, you should confirm what it is made of. The material must be compatible with

the conductor application. This property is vital as it will determine how strong the tension clamp fastening fitting is.

Our tension clamps are made of high-grade aluminum and cast iron materials.

The most attractive feature of these materials is their strength and electrical conductivity.

They are physically strong while at the same time compatible with different conductors.

Aluminum is also capable of functioning well under different conditions without degrading or getting damaged. It can

withstand extreme temperature ranges.

Alloys of aluminum can also be used as long as they meet the technical requirements of the tension clamp.

The surface treatment of this fitting is hot-dip galvanizing. According to the corrosive environment, the zinc layer

thickness should be adjusted within a certain range.

Post time: Jul-18-2022