What is Socket Clevis?

Socket clevis is also known as socket tongue is a very integral component of the pole line technology.

It is commonly used on overhead lines, transmission lines, and power lines.

It is a major component in pole line hardware which usually connects the socket type insulator and the tension clamp.

Have a look at this:

The connection of the socket clevis varies in different countries depending on the laws that govern pole line technology.

So, it is important to know the connection in your country before deciding to place an order for the hardware.

For instance, in Africa the kind of socket clevis used includes:

Socket tongue suitably used on “Aluminum Conductor Steel Reinforced (ACSR)”.

The outer diameter lies between 7 mm and 18.2mm (25 square millimeters and 150 square millimeters).

It was also used on “standard disc insulators of ball and socket type” with the diameter of the ball pin of 16 mm

Why You Need Socket Clevis?

As an integral part of pole line hardware, socket clevis is used for some purposes.

- It connects the socket type insulator and the tension clamp or the support.

- It is used as fitting in joining insulators of one string. Examples include“ball and socket, clevis and tongue connections, yoke plates for multi-string insulators.”

- It can also be used on power lines as an electric link.

- In overhead lines, it is used as an integral part of supplying electric energy to trains, trolley buses, and trams.

- In transmission lines, it is part of the system designed to help in conducting alternate currents in radio frequencies.

Main Components of Socket Clevis

A socket clevis is an assembly of various parts and components.

Even though they vary in designs and shapes, here are some of the most common parts.

1. Anchor shackles

It is a piece of metal usually U shaped and secured with a clevis pin and a bolt.

Also, it can be secured using a hinged metal loop which has a quick release locking pin mechanism.

It acts as the main link in different linking systems as they give quick connections and disconnections.

2. Clevis pin

It is an integral part of a clevis fastener which has three main components including clevis pin, clevis, and tang.

The pins are of two types including unthreaded and threaded.

Unthreaded pins have a dome shaped head at one end and on the other end, there is a cross hole.

To keep the clevis pin in place, a split pin or a cotter pin is used.

The threaded pin on the other end has formed heads on one side while the other side is merely threaded.

A nut comes in handy when the pin has to be put in place.

3. Clevis bolt

It can be used to act in place of a clevis pin even though it does not take the stress handled by the clevis pin.

They are made to take and maintain tension loads.

4. Cotter pin

It is also known as a split pin depending on the country it is being used in.

Remember, this is a piece of metal that acts as a fastener with ends that are bent at installation.

It is used in fastening two pieces of metal together.

5. Bolt

It is a type of fastener that has external male threads used and has similarities to a screw.

It is usually used together with a nut.

On one end there is the bolt head and on the other end is the external male thread.

6. Nut

This is a type of fastener that has a threaded hole.

It is used together with a bolt to fasten or join different parts together.

The partnership is put together with the combination of the threads through friction.

Apart from that, it depends on the stretching and compression of the parts that are joined together.

Technical Specification of Socket Clevis

Before you buy a socket clevis, it is important to pay attention to the following key technical specifications:

1. Material Type

The type of materials used in making the socket clevises are steel and iron.

These materials are preferred because they are strong enough and can withstand the weight and stresses.

2. Surface Treatment

Socket clevises are passed through the process of hot dip galvanization to make them corrosion resistant.

Hot dip galvanization involves dipping the iron or steel clevis in zinc to plate it and give it the final smooth touch.

The iron and steel are bathed in molten zinc at a temperature of 449 degrees Celsius.

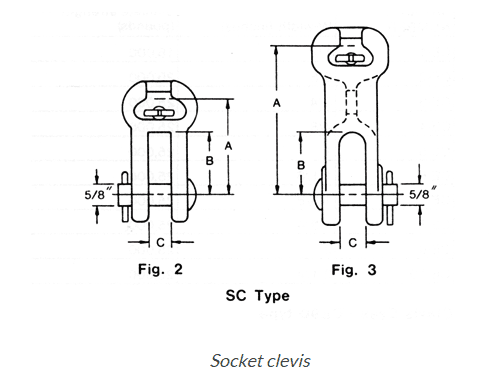

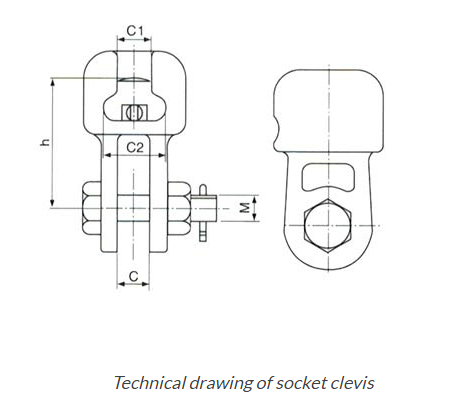

3. Dimensions

The dimensions on the socket clevis vary depending on the size of the device.

Also, the bigger the size of the socket clevis the greater the dimensions.

The width and length are measured in millimeters while the weight is determined in kilograms.

4. Design

The design on the socket clevis is dependent on the company that manufactures it.

Normally, the customer has a say in the kind of design that he will require and for the task, it would perform.

The design of the socket clevis has to match the function that it was meant to perform.

5. Rated Load

The rated load on the socket clevis depends on the amount of power it will be handling.

The customer has to specify the function that the clevis will perform before purchasing the clevis.

The manufacturer will then advise on the most appropriate socket clevis concerning the rated load.

6. Weight

The weight of the socket clevis depends on the size of the device, the material used in making the device.

Other materials are heavier than others resulting in a great difference in weight.

The dimensions such as width, length do vary and so does the weight.

Socket Clevis Manufacturing Process

The process of manufacturing starts with heating, molding, annealing and then hot dip galvanization.

The processes mentioned above are risky and usually left for industries to perform.

Materials: the main raw material required is iron and a mold of the socket clevis.

Some machines are required for this process that are quite expensive.

This is the reason why it is left for the major industries such as Jingyoung to manufacture.

Caution: The process of making a clevis involves handling iron at very high temperatures.

It is a dangerous process and you have to be very cautious when handling molten iron.

You should also put on protective clothes and boots to protect you from any accidents that may occur.

Measurements: This is the process of getting the right sizes of the material to be used in manufacturing.

It is done according to the customer’s specifications in case of custom-made socket clevises.

The material is cut into the required pieces before being subjected to the other processes.

Heating Process: Cast iron is heated at very high temperatures so that it can melt.

Cast iron is the most preferred material because it melts at lower temperatures as compared to others.

It is transformed from a solid to a liquid state.

Molten iron is very hot and a lot of caution should be taken during this process.

Apart from the low melting, cast iron has good fluidity, excellent machinability, wear resistance and resistant deformation.

These properties make it the most preferred material used in making the socket clevis.

Molding: Molten iron is then poured into the mold of the socket clevis.

The mold is shaped in such a way that it has a hole resembling a socket tongue.

Liquid iron takes the shape of the mold which is the shape of the socket clevis.

Annealing: The third step is annealing which is a form of heat treatment that alters the microstructure of the iron.

It is a process that makes the socket clevis achieve its strength, hardness, and ductility.

Cooling: the fourth step involves leaving the molded iron to cool.

The cooling process is slow to allow the mold to stay in shape and not to crack.

Hot dip galvanization is the last process that the cooled down iron is taken through.

This involves coating the socket clevis using Zinc to protect it from corrosion.

The socket clevis is dipped in molten zinc at a temperature of 449 degrees Celsius.

At this point, the socket clevis is ready and is inspected to make sure it is good for use.

How to Install Socket Clevis?

Installation of the socket clevis is a process that requires you to have the poles in place before attempting installation.

Make sure that all the materials are in place too and a ladder is available to elevate you to the required heights.

- The insulator strings should be assembled on the ground before climbing the pole. Assembling the strings on the ground is easier as compared to doing it at the top of the pole.

- The insulators and the fittings are also installed on the ground and also at higher altitudes.

- To increase the efficiency of the installation, especially when construction conditions are in place, ground assembly is preferred.

- Assembly at high altitudes is done when the construction has restrictions.

- During the installation process of insulators and fittings at high altitudes, workers carry tools, ropes and steel tapes up the ladder.

- The position of installation of the cross arm is marked and with the assistance of a rope, it is pulled.

- The cross arm is installed in place then other hardware such as the insulator and insulator strings are installed.

The socket clevis is a very important component of the pole line hardware and is installed by professionals.

The kind of task it is expected to perform requires people with experience to install it as mistakes are not accepted.

It is also very dangerous to attempt installation without the help of other people meaning it cannot be done individually.

Post time: Sep-17-2020