Reliable power supply is an important indicator of the power supply capacity of power supply enterprises, which reflects the

degree of satisfaction of users’ power demand, and is also an important part of evaluating power quality. The reliability of the

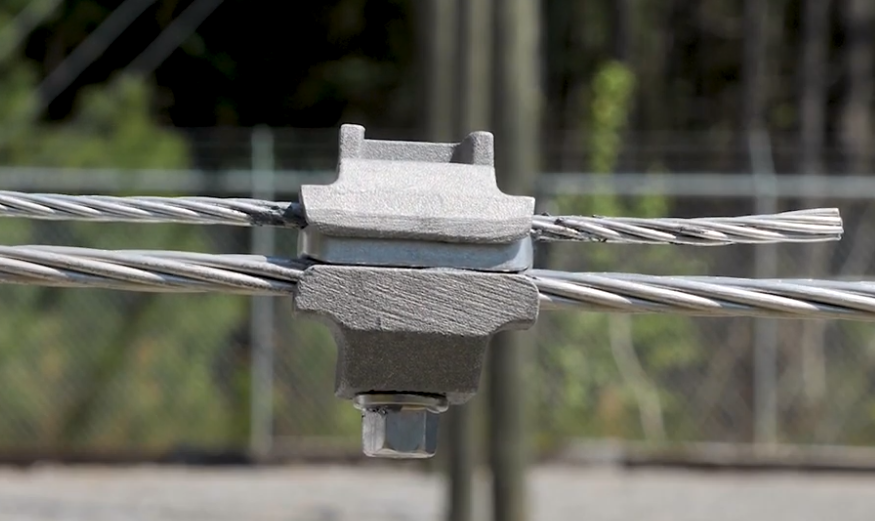

line tool is an important factor affecting the reliability of the power supply, and the transmission line drainage and trench clamp

is the weak link of the electrical connection of the transmission line. Although the structure is simple, it is the key part of the

load current and plays an important role. In view of the accidents that often occur during the implementation of live work, this

paper analyzes the reasons for the failure of the parallel groove clamp, which are mainly caused by the improper selection of

the connecting hardware and the imperfect construction technology. Therefore, in response to these problems, the design A

kind of double-parallel groove wire clip installation hardware that is convenient and quick to operate, and applied in the distribution

network line. The double-parallel groove wire clip installation hardware has good electrical characteristics, which solves the

connection problem of wires of different cross-sections, and solves different problems for the power industry. Diameter wire

connection problem provides a new way.

The status quo of parallel groove clamps, improper selection of connecting hardware At present, the connection fittings for user

drain lines widely used in distribution network lines are JB-type parallel groove clamps. This kind of common B-type parallel

groove clamp can only clamp the same diameter aluminum stranded wire and steel core aluminum stranded wire. For the

JB-3 type parallel groove wire clip, it is suitable for all conductors within the range of 120-150 mm2 cross-section from the design

concept, and has a wide range of applications. The trunk line of the fault line adopts the JKLGYJ-10-120 type insulated wire with

a cross-section of 120mm2, the user drainage wire adopts the JKLGYJ-10-70 type of insulated wire with a cross-section of 70mm2,

and the connecting hardware adopts the B-type parallel trench clip. Since the JB-3 type parallel groove wire clamp can only

connect wires of the same cross section, when the B-3 type parallel groove wire clamp is selected to connect the main line with

a cross section of 120 mm2 and a drainage wire with a cross section of 70 mm2, it will cause uneven stress on the bolt, The contact

resistance increases, causing the connection point to heat up or even burn, causing the power supply line to trip and power off.

Post time: Mar-28-2022