High quality copper ground rod and earth rod clad earthing rod

Copper Bounded Earth Rod

Copper Bonded Earth Rod is a product that helps in dissipating the fault current to help your assets being damaged from the hazards of fault

current. Copper bonded rod is most widely used as grounding electrodes. Copper bonded rods are manufactured standard micron which is

internationally accepted.

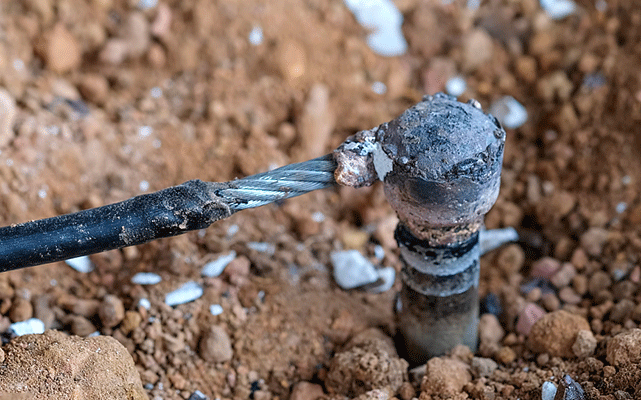

The copper layer is bonded to steel core through an electrolytic process that ensures a perfect and tough bonding between the steel and the

copper the ground rods are fully covered with copper without any cracks, holes, cavities etc. and prevent exposure of the steel core to soil

and moisture. Therefore it can resist corrosion better and has capacity of being driven to great depths.

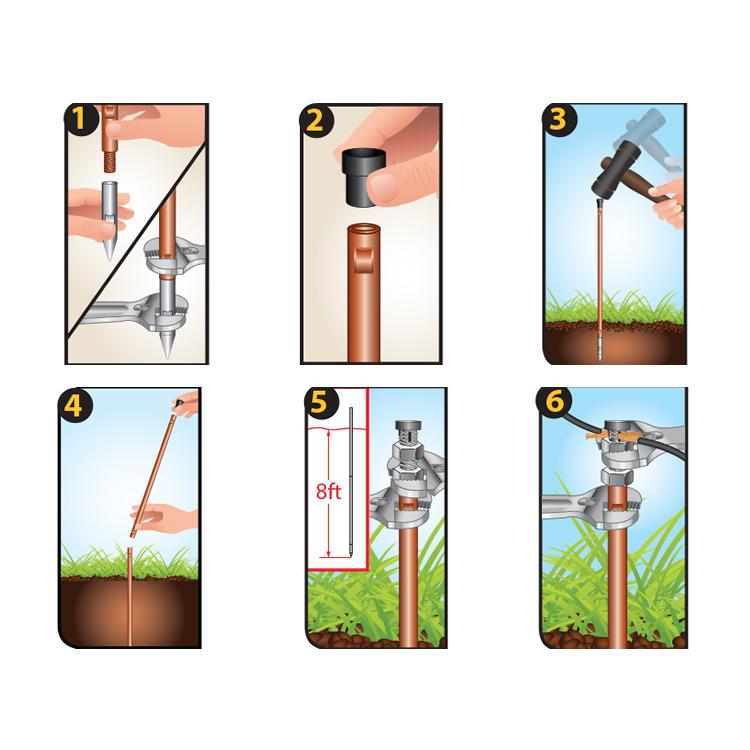

These sectional earth rods are threaded on both ends to allow rod-to-rod connections with couplings to meet customers’ specific needs.

Such procedure permits up to 100-feet depths to be reached with no damage to the threads or the couplings.

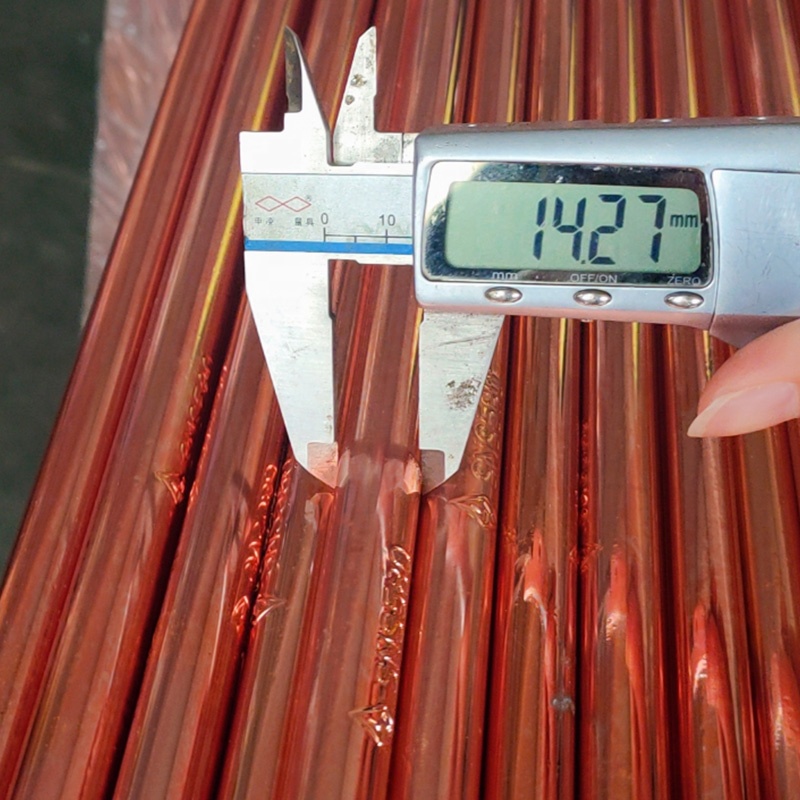

rod is applying 99.95% pure copper on low carton steel by electroplating. It is a molecularly bonding. Copper layer is usually 254 microns.

Popular diameters are 1/2”,5/8”and 3/4”.Earth rod can be threaded and tipped.

We introduced automatic electroplating production line so as to guarantee the electroplating quality and large production capacity.Copper

bonded earth rod has advantages of high conductivity and anti-corrosion. It is easy to install.

FEATURES

• 99.95% pure copper and low carbon steel.

• copper layer ≥ 254 microns.

• tensile strength : 450-750.

• capable of being bent 180 degrees without cracks.

• usage life more than 50 years.

APPLICATION FIELD

· Railway transportation

· Storage tank

· power station

· Petrochemical plant

· Transmission and transformation line

· Railway

· Photovoltaic power generation

· Communication base station

· Network computer room

Relevant regulations on copper clad earth rod installation

1. The buried depth of the top surface of the grounding rod shall meet the design requirements. If there is no requirement, it shall not be less

than 0.6m. Angle steel and steel pipe grounding electrodes shall be arranged vertically. In addition to the grounding electrode, the vertical part

of the outgoing line of the grounding body and the welding part of the grounding device shall be treated with anti-corrosion; before the anti-

corrosion treatment, the staff must remove the rust on the surface and remove the residual welding points at the welding position.

2. The distance between vertical grounding electrodes shall not be less than 3-5 times of its length. The spacing of the horizontal grounding body

shall meet the design requirements. When there is no design regulation, it should not be less than 5m.

3. In addition to the ring-shaped grounding electrode, the buried cover of the grounding electrode shall be 3m away from the building. It shall

also be more than 3m away from the building access day or sidewalk. If it is less than 3m, the pressure-equalizing belt method shall be adopted

or a 50-90mm thick asphalt layer shall be laid on the grounding device, and its width shall exceed 2m of the grounding device.

4. After the grounding rod is laid, there shall be no stones and construction waste in the backfill of foundation pit.

5. The soil taken out shall not have strong corrosion. The backfill shall be compacted in layers.

6. When the grounding device is composed of multiple sub grounding devices, a disconnection card which is convenient for separation shall be

set according to the design requirements.

Post time: Oct-19-2022