Factory Cheap Hot Edpm Cold Shrink Tube - Heat Shrink Boots – Yongjiu

Factory Cheap Hot Edpm Cold Shrink Tube - Heat Shrink Boots – Yongjiu Detail:

Application

It can be safely used in protecting cable end up to 36kV against flashover, or surges induce during working life in switch gear and transformer boxes.

Feature

1.Preferable electrical appliance function

2.Reliable insulation

3.Superior hermetic sealing

4.Excellent heat /cold proof, waterproof, Anti-aging ,

5.Widely used at the field of electric power, electronic, petroleum, chemical engineering, construction and communication

The production of heat shrinkable tubing must first select the appropriate masterbatch, and then select the auxiliary materials to produce specific

The thermal housing casing.

1. The production process of heat shrinkable tube is firstly the production of polyene leech masterbatch: combining various polyene leech base materials with various functional auxiliary materials

The materials are weighed according to the formula ratio and then mixed: the mixed materials are put into a twin-screw extruder and pelletized to produce a polyene leech functional masterbatch.

2. Product molding process: according to the shape of the product, two methods of single screw extrusion and injection molding can be used.

For processing and production:

1. Single-screw extrusion type: mainly used for extrusion molding of heat sink pipes, such as single-wall heat-shrinkable tubes, double-wall heat-shrinkable tubes with glue, and medium thickness

Wall heat sink pipes, high pressure busbar heat sink pipes, high temperature heat shrinkable pipes and other products are all processed and formed by single screw extrusion.

The heat shrinkable tube production line should have the following equipment: extruder (heat sink tube forming), production mold, cooling water tank, tension device, and

Disk device, etc.

2. Injection molding: mainly used for the production of heat-shrinkable special-shaped parts, such as heat sink caps, heat-shrinkable umbrella skirts, heat-shrinkable finger cots and other products

They all use injection molding, and production equipment should include injection molding machines and injection molds.

3. The next important step is radiation cross-linking. The products formed by extrusion or injection molding are still linear molecular structures.

Structure, the product does not yet have the “memory function”, and the performance of temperature resistance, aging resistance, and wear resistance is not enough.

Change the molecular structure of the product. The method we usually use is radiation crosslinking modification: electron accelerator radiation crosslinking, cobalt source radiation

Cross-linking, peroxide chemical cross-linking, at this time the molecule changes from a linear molecular structure to a network structure. Extruded products are passing

After cross-linking, it has a “memory effect”, which greatly enhances the temperature resistance, mechanical properties, and chemical properties of the heat shrinkable tube. The specific table

Now the heat sink tube has changed from the state of tolerance to incompatible, aging resistance, abrasion resistance, and chemical corrosion resistance.

4. Expansion molding: The product modified by radiation crosslinking already has a “shape memory effect”, and it has a high

Non-melting performance under temperature. After heating at high temperature, vacuum blowing and cooling, it becomes the finished heat shrinkable tube, and then according to the tube

The actual situation of the finished product packaging and closing can also be cut and printed according to customer needs. Neutral normal packaging is also available.

Performance

| Test | Test Method | Requirement |

| Tensile strength | ASTM D 2671 | ≥12 Mpa |

| Elongation at break | ASTM D 2671 | >400% |

| Tensile strength after heat aging | ASTM D 2671/120℃,168h | ≥8.5 Mpa |

| Elongation at break after heat aging | ASTM D 2671/120℃,168h | ≥200% |

| Volume resistivity | IEC 93 | 1013Ω.cm |

| Dielectrical strength | IEC 243 | ≥15KV/mm |

| Flame retardancy (oxygen index) | ASTM 4589 | ≥25 |

| Water absorption rate | ISO 62/23℃,14 days | ≤1% |

|

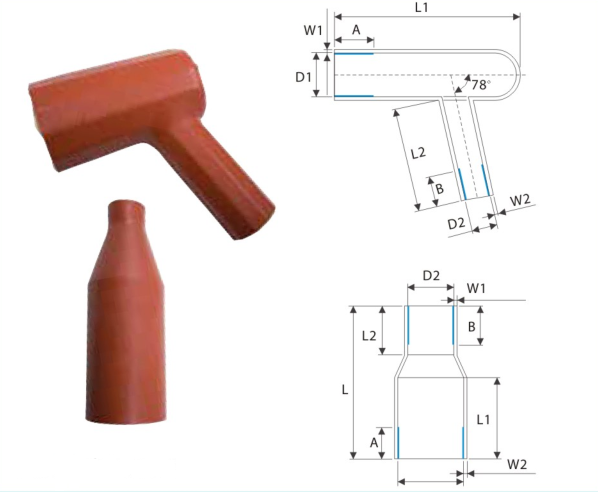

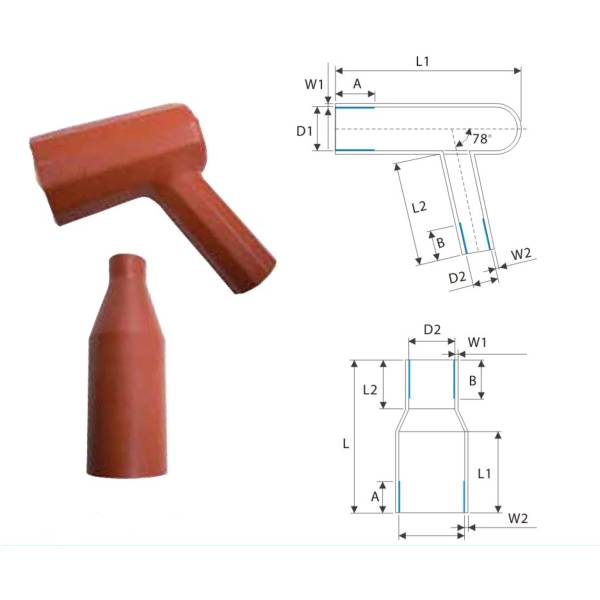

Type |

Model number |

Expanded (mm) |

Recovered(mm) |

|||||||

|

D1(Min) |

D2(Min) |

D1(Max) |

D2(Max) |

L1(±10%) |

L2(±10%) |

L(±10%) |

W1(±10%) |

W2(±10%) |

||

|

Right Angle |

SHMR-1(80/36-35-18) |

80 |

35 |

36 |

18 |

170 |

125 |

- |

4.2 |

3.5 |

|

SHMR-2(80/36-50/18) |

80 |

50 |

36 |

18 |

170 |

125 |

- |

3.8 |

3.5 |

|

|

SHMR-3(95/38-70/28) |

95 |

70 |

38 |

28 |

160 |

140 |

- |

4.2 |

4.8 |

|

|

Straight |

SHMR-4(80/35-34/20) |

80 |

34 |

35 |

20 |

145 |

30 |

220 |

3.2 |

3.2 |

|

SHMR-5(80-35/58-20) |

80 |

58 |

35 |

20 |

145 |

30 |

220 |

3.2 |

3.2 |

|

Product detail pictures:

Related Product Guide:

Sticking for the belief of "Creating items of top of the range and creating buddies with people today from all over the world", we normally put the interest of shoppers in the first place for Factory Cheap Hot Edpm Cold Shrink Tube - Heat Shrink Boots – Yongjiu , The product will supply to all over the world, such as: Toronto, Victoria, Denmark, Our market share of our products has greatly increased yearly. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future. We are looking forward to your inquiry and order.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.